Automatic Generation Control (AGC), on an Energy Management System (EMS), is critical for responding to frequency deviations on the system network. AGC also balances the Net Actual Interchange to the Net Scheduled Interchange. A properly tuned AGC system ensures unit control requests are effective (accurately sized controls) and efficient (minimal number of controls to reducing oscillations). Most, if not all, AGC systems require periodic tuning to achieve these goals.

Tuning of AGC controls can improve market system compliance by minimizing uninstructed deviation changes. A well-tuned AGC system is also key to integrating renewables. Tuning enables the AGC system to be highly responsive when reacting to unplanned changes in the output of the as-available generation.

Conversely, a poorly tuned AGC system can result in numerous undesirable outcomes, including higher O&M costs, increased unit wear and tear from excessive controls, and decreased unit responsiveness from ineffective controls. These unwanted outcomes can result in tens of thousands of dollars a month in excess costs.

What to watch for

Your AGC system may benefit from tuning if:

- Changes have been made to the local RTU or unit controller that effect how controls are implemented at the generating plant. It is common for these changes to not be coordinated with the EMS support staff responsible for the AGC system.

- A generating unit has problems maintaining a particular MW output or overshoots the desired changes in control direction (Raise controls vs lower controls, i.e., hunting).

- Under AGC control, a generating unit is not able to respond at the ramp rate that the generating plant staff knows the unit is capable of.

- During a frequency deviation event, the subsequent unit controls fight against the local governor action, i.e., controls are not frequency coordinated.

- ACE is crossing zero frequently.

- The AGC system has been upgraded to a newer product version which may or may not include new features.

- It has been more than five years since the AGC system was tuned even if there have not been identifiable changes to the unit controls at the generating plant, i.e., unit control response drifts over time.

Brad has helped customers work through a variety of AGC/Unit control issues. Sometimes, control problems can be avoided by improving communications. “In one case,” says Brad, “[the customer’s] AGC/Unit controls were tuned to a satisfactory level, and only one year later the customer requested another tuning, due to problems with control. The follow-up tuning found that over half of unit controls needed to be retuned due to changes to the unit controller by plant personnel that were not communicated to operations staff.”

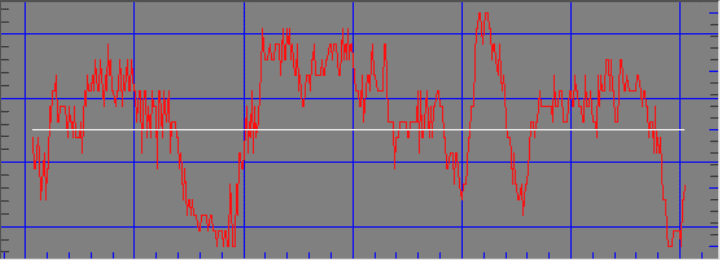

In another case, the customer’s AGC system had not been tuned for approximately 10 years. This resulted in significant oscillations in the unit controls as well as the ACE Regulation controls. For many systems in need of tuning, says Brad, the savings can be significant. “After completing the tuning, and comparing the before and after operations, conservative estimates of savings was in the range of $100,000 per month.”

AGC Evaluation

Some sites may benefit from an outside review of their AGC performance, including observation of how AGC features are being used and analysis of how they might be better leveraged. PSC offers customers an onsite review by an AGC subject matter expert to assess the overall state of AGC “health” and discuss of possible areas for improvement. This assessment culminates in a written report that may include recommendation for AGC tuning, as well as discussion of other AGC features that could benefit your operation.

How It’s Done

PSC supports customers with routine tuning of their AGC system. This tuning is focused on the controls to the generating units as well as the ACE Regulation requests for the Balancing Area. Local staff are encouraged to participate as a training activity. This can include technical staff from the generating plants. This service includes a report discussing the problems found, the changes made, and recommendations for future improvements (most of which can be addressed internal to your organization).

PSC experts like Brad Nelson perform AGC/Unit tuning on site.Overall observations are made and notes are taken to describe the “starting point” of the system.

As generating units are made available for testing/tuning, open-loop controls are issued and their response to those controls is analyzed. This provides a starting point for setting the Tuning parameters. Tuning parameters are further adjusted and confirmed/refined using closed-loop controls.

In a recent example, the senior plant technician was participating in the unit tuning. When the unit response significantly over-shot its target and then pulled back much more than expected, the plant technician knew exactly what the problem was. He called another technician at the plant who adjusted a setting in the local unit controller/governor which significantly improved the unit response. Overall, the tuning activity was much more successful with his participation.

Throughout the AGC/Unit tuning process, the system response to ACE Regulation is observed with corresponding BA level parameters adjusted.

If any of the control problems described above apply to your system, please contact us to discuss improving your system’s performance. We may be able to do an initial evaluation via video conference.